May 20, 2021

Innovation is about challenging assumptions or solving problems, encouraging thinking in a new way to transform what currently exists. It is the driving force behind the inventions that have improved our world. Using science, technology, engineering, and mathematics (STEM) as a core part of the innovation equation allows innovators to thoughtfully and insightfully evaluate problems and create real-world applications for solutions.

S&ME X Branch Technology

In 2016, S&ME Chattanooga began a partnership with Branch Technology, a construction-tech company located in Chattanooga, TN. Branch 3-D prints construction components that bring unprecedented design freedom and resource stewardship to the construction industry.

Branch Technology robots.

How do you test the strength of a material new to the market? S&ME set out to accomplish this with partner, Branch Technology.

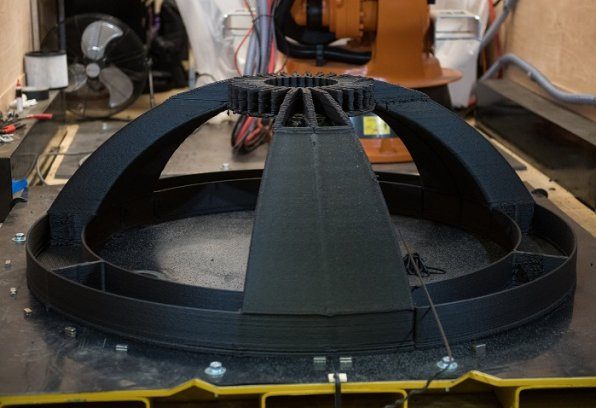

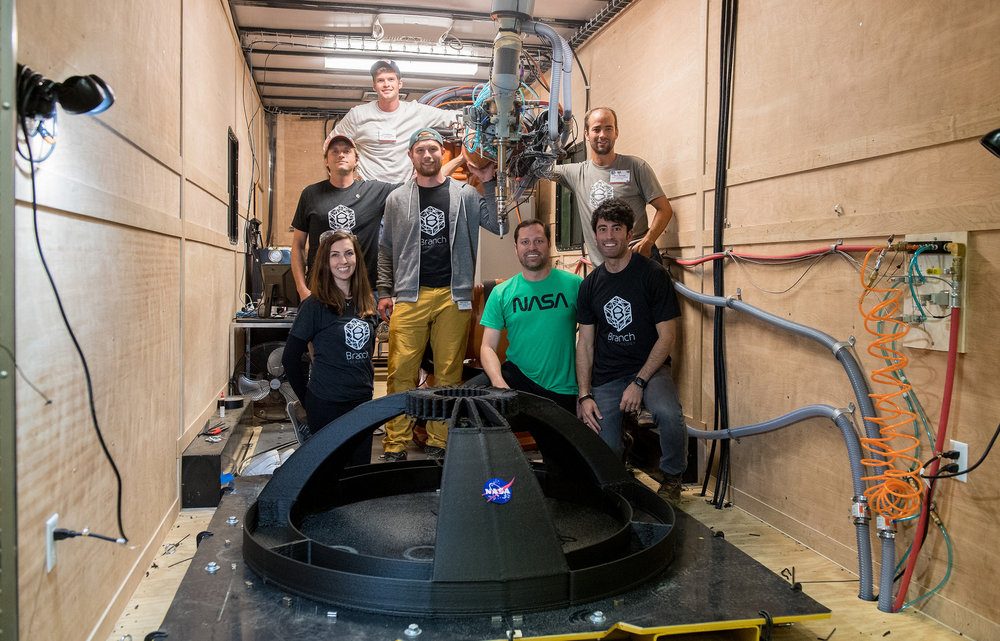

In 2017, NASA held an open competition to advance construction technologies for robots to create off-world habitats, one of many steps in NASA’s vision to construct extra-terrestrial habitats. The groups were tasked with producing three beams, three cylinders, and a dome out of indigenous Martian regolith and recyclable materials. Branch Technology won all segments of the competition, while S&ME provided the initial testing for the material. Read more on this here.

The structures we provided testing for were able to take double the load of a competing dome in a stress test.

Branch Technology dome.

The Branch Technology team pictured at the NASA competition.

S&ME & Branch Technology Partnership

S&ME Project Manager, Lucas Simington

S&ME Project Manager, Lucas Simington, collaborates with the Branch team to establish test procedures. Branch approached our Chattanooga team needing assistance in testing a product that no one had seen and did not have specifications. With the assistance of Senior Engineer, Mr. Jeffrey Pepper, PE S&ME established test methods based on the applicable portions of the ASTMs used for compressive strength of CMU and flexible strength of concrete beams.

Lucas says,

“We’re enjoying this collaborative process and working through this together. It is important for Branch to better understand the parameters of a test and how it functions since they are designing and building structures from scratch. It is exciting to see that their products can exhibit higher strengths than typical construction materials with much lower unit weights.”

Currently, Branch is working on a submittal for the moon, and our team will also complete construction materials testing.

“S&ME has allowed Branch to begin characterizing the structural properties of its patented Freeform 3D printed components. With a new construction product comes myriad codes and certifications that must be passed before market adoption can occur. Testing samples with S&ME is our first line of information about how a new material will perform after it is printed. Their ability to rapidly test and provide accurate and digestible reports has been critical to our research and customer engagements.”

-Branch Technology

More on Branch

The group at Branch created a revolutionary new additive manufacturing process called Cellular Fabrication, C-Fab ©, and construction materials 3D-printing technology called “Freeform”, enabling the material to solidify in open spaces to be manipulated in any form. Coupled with “Freeform,” Branch’s process combines industrial robotics and sophisticated geometric algorithms. These capabilities and innovative differentiators have quickly set them apart in the construction field, with the group even completing record-breaking projects, such as the world’s largest 3-D printed structure. More samples of some of Branch Technology projects below.

Nature Clouds Installation

Tennessee Valley Federal Credit Union

One City Pavillion