K.C. Industries, Inc.

K.C. Industries Properties, L.L.C. (KCIP) owns approximately 120 acres of property east of Mulberry, Florida. This property was formerly owned by Kaiser Aluminum & Chemical Corporation (KACC), a company that operated a small chemical facility. Past operational practices resulted in deposition of lime sludges in remnant “pits’ from phosphate mining. These sludges contain elevated concentrations of sodium and chloride and, to a lesser degree, fluoride and arsenic. Contaminants also affected the groundwater.

When KACC owned the property, S&ME assessed the extent of groundwater contamination and evaluated the chemical and physical properties of the lime sludge. S&ME conducted several remedial alternatives evaluations. S&ME also designed, installed and operated a groundwater recovery system to control and contain the contaminated groundwater.

More recently, KCIP hired our team to evaluate remedial alternatives. After selection of the desired alternative, S&ME prepared a remedial action plan submitted and approved by the Florida Department of Environmental Protection (FDEP). After approval, S&ME prepared the design and bidding documents and assisted KCIP in selecting a contractor to implement the remedial action.

The remedial action plan addressed several challenging conditions at the site. Much of the lime sludge is under water. In addition, the fine-grained sludge does not rapidly settle out when dredged. The sludge is very soft and settlement of the sludges over the long term could be significant. As a result, this raises issues with the integrity of any cap installed over the stored material. One alternative was encapsulation in place. Another alternative involved consolidation into one location surrounded by a slurry wall to minimize horizontal movement of contaminated water and capping. Finally, the team considered the use of additives to solidify the sludges in place.

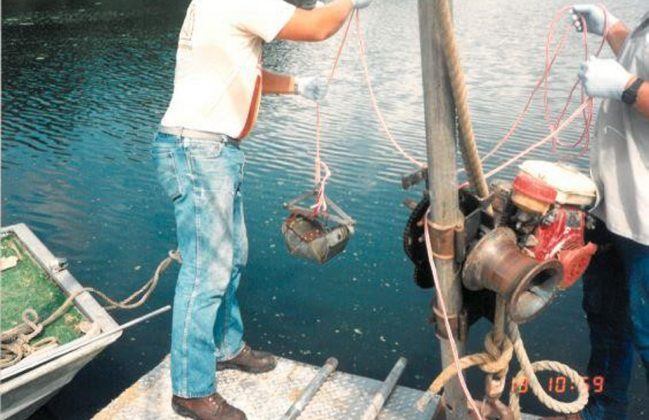

S&ME prepared and submitted a draft Remedial Action Plan (RAP) to the FDEP. The proposed remedy consisted of dividing the North Pond with the construction of an earthen north-south dike and consolidating all of the waste materials in one side of the North Pond. Transfer of the material occurred by convention dredging, “environmental” dredging, and conventional excavation and earthwork. Once the transfer was complete, the area was capped and a slurry wall was installed along the alignment of the divider dike. The design incorporates features to accommodate long-term large settlement of the consolidated material. S&ME submitted the final RAP in March 2012. Construction began soon thereafter and completed in 2014.

Highlights

- Large-scale environmental remediation

- S&ME conducts semi-annual groundwater monitoring in accordance with FDEP approval