Pavement

Pavements represent a large portion of transportation infrastructure, and their structural and functional performance are essential for safe and efficient operations and movement of personnel and consumer goods.

Proper pavement testing, analyzing, and applying the most appropriate rehabilitation and preservation methods can deliver cost savings and long-term use.

S&ME engineering services support the entire pavement lifecycle and include:

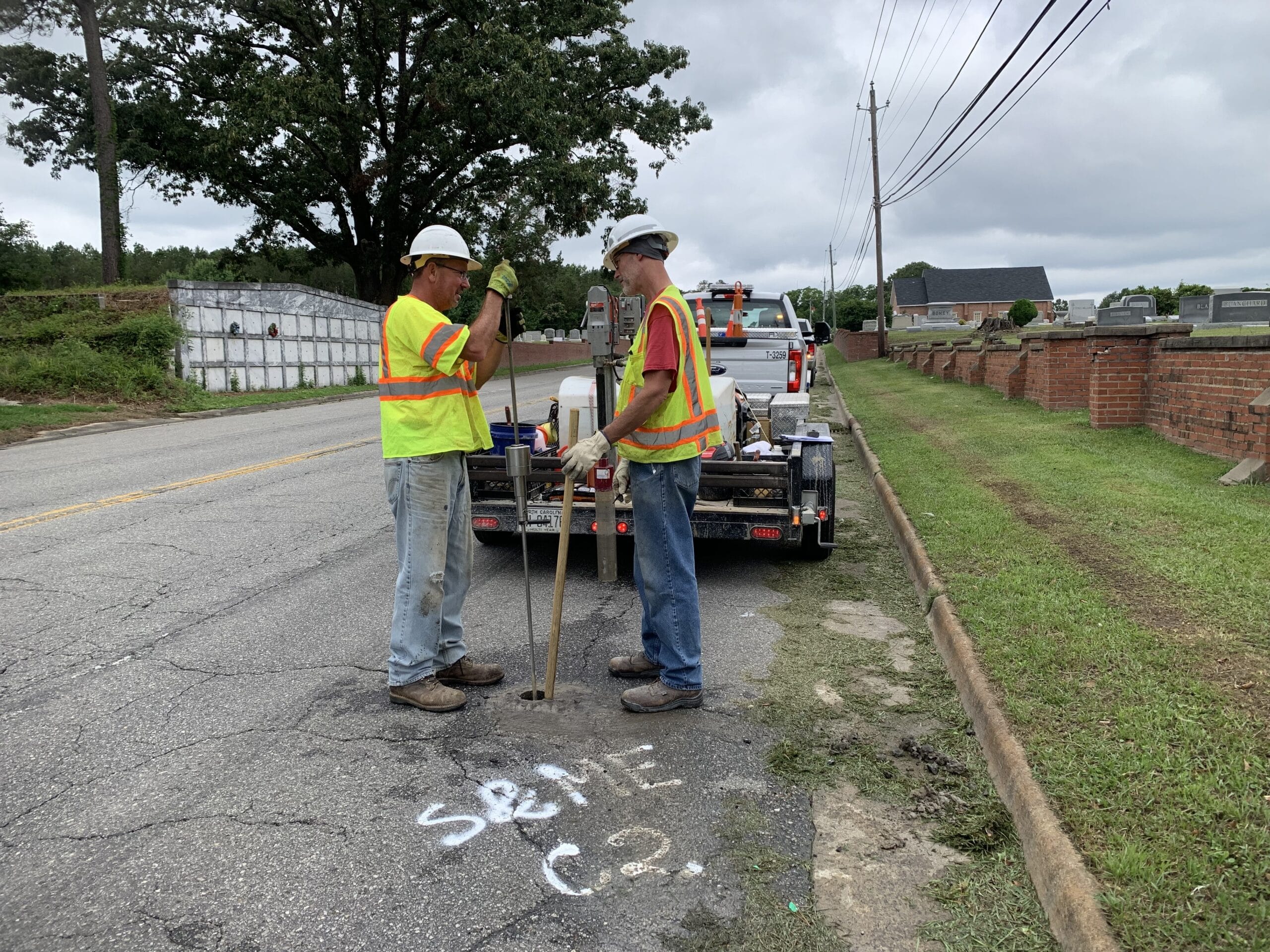

- Pavement coring

- In-situ pavement and subgrade testing

- Subsurface investigation

- Pavement structural design

- Pavement smoothness and friction testing

- Pavement condition surveys

- Materials selection

- Pavement mix designs

- Construction quality control

- Long-term pavement management and rehabilitation strategies

Pavement Testing

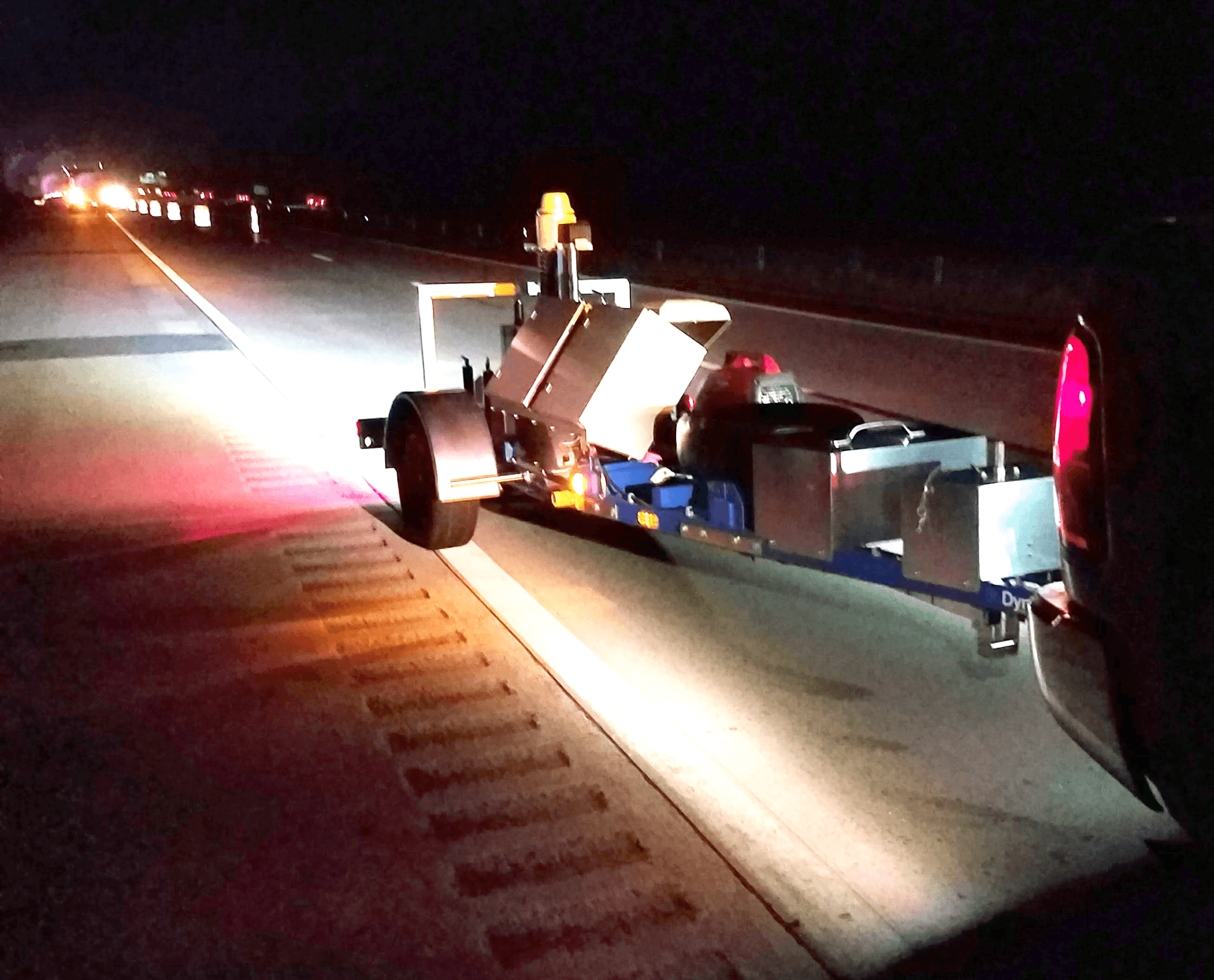

- Non-destructive pavement testing

- Falling Weight Deflectometer (FWD)

- High-speed Ground Penetrating Radar (GPR)

- Dual Line Inertial Profiler (IRI)

FWD calculates pavement structural condition.

GPR calculates pavement thickness.

IRI calculates pavement roughness.

Read more on 3 Outcomes of Pavement Testing.

Pavement Analysis and Design

We provide clients with pavement designs based upon repeatable, in-situ pavement properties, are fully versed in AASHTO Design procedures, and have been on the leading edge of implementing and utilizing the Mechanistic-Empirical Pavement Design (MEPDG) design procedures.

S&ME material testing laboratories offer a full range of material testing services for soils and pavements to facilitate pavement mix design and forensic analysis efforts.

Pavement Rehabilitation and Management Strategies

S&ME assists clients with managing their pavement assets and applying cost-effective, practical maintenance applications to extend the life of their existing pavements by assessing existing pavement structural and functional conditions, estimating remaining service life, and developing alternative pavement preservation and rehabilitation strategies based on life-cycle cost analysis.